Technical Description-Machine Vision Systems

Machine vision has evolved to become a fast and reliable tool for quality control inspection. It is now becoming a fast and reliable tool for quality control inspection. As initiatives such as Six Sigma and TQM push quality standards to the highest levels, machine vision can aid manufacturing organizations in reaching their quality goals. It is deployed to do things more quickly and accurately than humans and at a lower cost.

Machine vision is a specific application of computer vision that enables cameras and computers to replace humans in evaluation and inspection tasks that are precise, repetitive or high speed. Today, more than ever, machine vision is being used to ensure quality in manufacturing everything from diapers to the most advanced computer chips.

How it works

A machine vision system acquires images of an object and then uses computers to process, analyze and measure various characteristics of that object so decisions can be made. These decisions may involve characteristics that cannot be seen by the human eye or analyzing image data for measurement purposes. Qualifying parts as "good" or "bad" based on their shape or size is the cornerstone of quality inspection systems. In addition, products built in stages can benefit from inspection throughout the process. Because each production stage has a cost per unit associated with it, eliminating bad parts early in the process can save money and improve efficiency. To maximize the effectiveness of machine vision, consider various ways to help the system to see possible problems, for example, by mechanically positioning the part under inspection, and using lighting and optics that clearly show the defects. Specific systems can be customized to a particular industry, or company's needs, but the basics are the same.

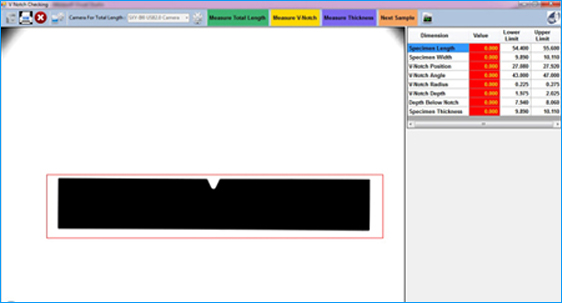

Magnification 1 (15 X)

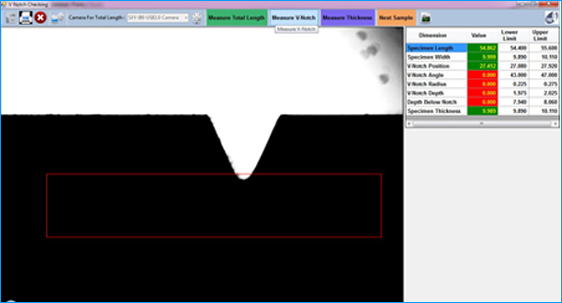

Magnification 2 (90 X)

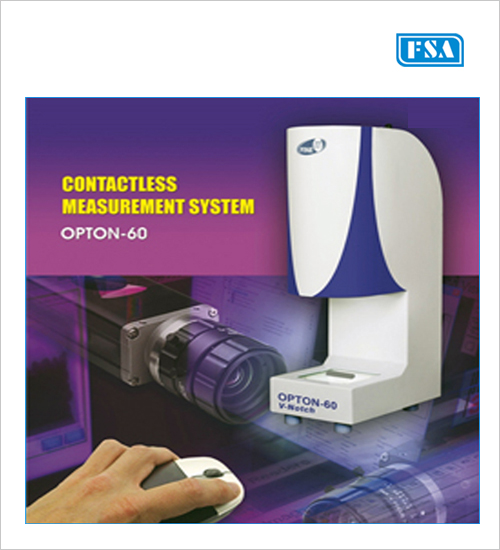

OPTON-60-VNotch

Measurement Parameters Opton-60-VNotch is special purpose machine for V-Notch measurement as per ASTM standard “ASTM E23”. The detailed measurement parameters are as follows:

| Parameter Name | Required Values | Measurement Resolution of system |

|---|---|---|

| Specimen Length | 55 mm (+0, -2.5 mm) | 0.04 mm |

| Specimen Length | 10 mm (+/-0.075 mm) | 0.02 mm |

| V-Notch Position | 27.5 mm (+/-1 mm) | 0.04 mm |

| Specimen Thickness | 10 mm (+/-0.0.075 mm) | 0.02 mm |

| V-Notch Angle | 45 deg (+/-1 deg) | 0.2 deg |

| V-Notch Radius | 0.25 mm (+/-0.025 mm) | 0.005 mm |

| V-Notch Depth | 2 mm (+/-0.025 mm) | 0.005 mm |

| Depth below V-Notch | 8 mm (+/-0.025 mm) | 0.05 mm |

Measurement Time

As mentioned above, there are 2 magnifications in the machine. By changing the knob, this magnification can be changed. Also, to measure the Width and the Thickness the component needs to be rotated by 90 degrees. Thus, there 3 measurement sets as described below:

| Set Number | Component Position | Knob Position | Measurement Parameters |

| 1. | V-Notch visible on screen | Magnification 1 (15 X) | Specimen Length Specimen Width V-Notch Position |

| 2. | V-Notch visible on screen | Magnification 2 (90 X) | V-Notch Angle V-Notch Radius V-Notch Depth Depth below V-Notch |

| 3. | V-Notch not visible on screen (90 degree rotated component at same position) | Magnification 1 (15 X) | Specimen Thickness |

| Each of the above measurement set will take 2 seconds to measure the dimensions after button click. | |||

Overall Specifications

The overall specifications for OPTON-60-VNotch are as follows:

| Model | OPTON-60-VNotch |

| Camera* | CMOS, Sony 2/3" chip |

| Lens | Dual magnification (15X and 90X) |

| Magnifications | Dual (15x, 90x) |

| Field of view * | 64 x 48 mm (for 15x) and 10x7 mm (for 90x) |

| Illumination | Back Light Illumination - LED Ring array (White / Green Light) |

| V-Notch Measurement Parameters | With 15x Magnification • Total Length, Width, V-Notch Position, Thickness With 90x Magnification • V-Notch Angle, V-Notch Radius, V-Notch Depth, Depth below V-Notch |

| Operating ambient temperature | 10 - 60 deg C |

| Operating ambient humidity | 20% to 60% RH (no condensation) |

| Power Supply | 220 VAC, 50 Hz (Single phase) |

| Weight * | Approx 25 kg |

| Dimensions * | 350 x 350 x 970 mm |

* Specification may change in future.

Note: PC is not considered in the scope of supply.

The specifications of the PC should be as mentioned below:

Intel Core 2duo processor, 1.6 GHZ, Windows XP / 7 OS (32/64 bit), 2 GB RAM and free USB2.0 port (minimum 1)